Add: North Area of New & Hi-tech Park, Pingxiang City, Jiangxi Prov, China.

Tel:

+86 13387997914,

+86 799 3671932

Fax: +86 799-3671922

Postcode: 337000

Website: www.siton-china.com

DL2 Long Hole Drilling Rig

The hydraulic production drilling rig for mining is especially suitable for long hole rock drilling in Pillarless segmented mining. The drilling hole diameter is 64-89mm. The drilling hole depth is 30 meters.

| Rock Drill | ||

| Model | 1838ME | 2560 |

| Shank adapter | T38/T45 | T45/T51 |

| Hole diameter mm | 64-76/76-89 | 76-1115 |

| Max impact power Kw | 18 | 25 |

| Impact rate Hz | 60 | 44 |

| System pressure bar | 230 | 230 |

| Rotation motors | Separate rotation | |

| Rotation speed rpm | 0-215 | 0-130 |

| Max rotary toque Nm | 1070 | 1550 |

| Lub. air consumption L/s | 5-7 | 5 |

| Weight Kg | 175 | 195 |

| Noise dB(A) | <106 | <106 |

| Drilling Feed and rod bank | ||

| Model | TF18-4 | TF18-5 |

| Length mm | 3037 | 3412 |

| Drilling rod length mm | 1220 | 1525 |

| Propulsion force KN | 15 | 15 |

| Rod magazine (optional) | 11/12 | 11/12 |

| Drilling depth mm | 13.3/15.5* | 18.1/19.6* |

| Drilling hole diameter mm | 64-76 | 64-76 |

| * Rod put on manually for deeper drill hole depth demand. | ||

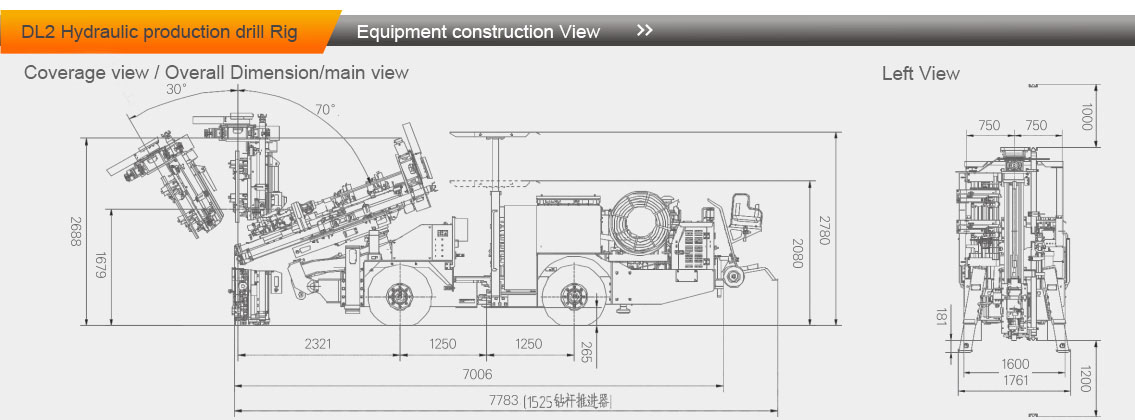

Boom and positioning

Feed extension(1220 drill rod)……850mm

Feed extension(1525 drill rod)……1155mm

Feed roll-over………………………360°

Feed Pitch…………………………30°/-70°

Boom Parallel movement……… 1500mm

Propelling feed top rear tip stroke…1200mm

Propelling feed top front tip stroke…1000mm

Propelling feed positioning

Digital display on the screen

Control method…………………wired/wireless

Air compressor system

Air compressor……screw/ZLS-07A-8-CA55

Motor power………………………………5.5Kw

Maximum displacement………………… 11.6L/S

Working pressure…………………………8Bar

Water system

Water pump type/Model…Centrifugal/CDMF5-20

Motor power…………………………3Kw

Maximum flow……………………80 L/min

Maximum working pressure ……………25bar

Control system

Electric remote control system

Function…anti-jamming, anti-empty drill

Electrical system

Total Installed power………………………63.5KW

Main motor power…………………………55Kw

Voltage………………………………………380V

Frequency……………………………………50Hz

Starting method…………………………Star delta

Thermal overload protection for electric motors

Impact timer

Digital voltage/current meter

Phase sequence indicator

Ground fault indicator

Battery charger……………………300W

Transformer………………………1300VA

Electrical cable volume……………80m

Hydraulic system

Hydraulic pump, for impact, positioning and propulsion

Hydraulic pump, for rotary

Oil pump unloading start

Max system pressure………………………230bar

Volume of Hydraulic oil tank………………165L

Low oil level indicator with shutdown function

oil tank with oil temperature gauge, temperature switch

Filtration accuracy…………………………10µm

Oil filter indicator

Stainless steel water cooler for hydraulic oil

Manual oil filling pump

Mineral hydraulic oil

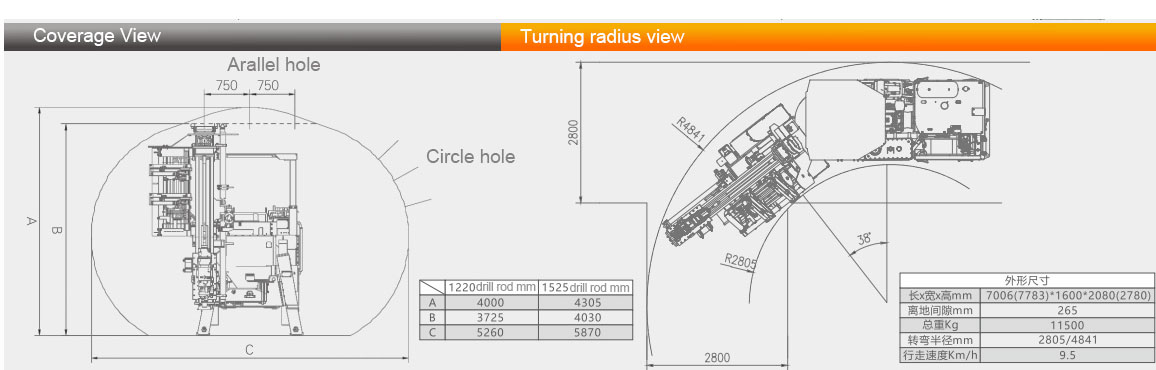

Carrier

Engine………………………………Yanmar

Rated power…………………………56.5KW

swivel seat

Articulated steering angle………………±38°

four-wheel drive

Hydrostatic Power Steering System

Hydrostatic transmission

Wheel reducer

Tyre……………………………………10.00-15

Departure angle…………………………… 15°

Approach angle……………………………20°

hydraulic front Outrigger…………………2pcs extensible

hydraulic rear Outrigger…………………2pcs

parking braking

Emergency and parking brake

Fuel tank volume……………………………60L

Electrical voltage…………………………12V

Battery…………………………………120Ah

Tramming lights………………………3×LED

Centralized Lubrication System for chassis

Catalytic converter/silencer

Dry powder fire extinguisher

Pneumatic grease gun

Machine wash water gun

Spirit level

Max. Working gradient……………………14°

Traveling speed……………………………9.5Km/h

Horns, warning lights and reversing alarms

Optional configuration/•--Standard ◎--option

Rock drill •1838ME ◎2238

Engine •Yanmar ◎Cummins

◎Rod magazine: storage 11/12pcs

◎Plateau: >3000Km

◎Automatic fire extinguishing system multiple nozzles

Remarks: Due to the continuous upgrading of products, the company reserves the right of final interpretation

| Over all dimension | |

| Lx Wx H mm | 9074 (9350) /2409/2318 (3018) |

| Ground clearance mm | 346 |

| Weight Kg | 17600 |

| Turning radius mm | 3656/6250 |

| Traveling speed Km/h | 13 |

The machine is compact and narrow, and it has unique advantages in the drift of about 3 meters. The propulsion mechanism adopts the tray type, which shortens the overall length and make the positioning on the tray easy and small shake, rod magazine is optional, suitable for 1.5 parallel hole and circle hole drilling .

Comprehensive equipment

Minimum adaptation: 3x3m long hole operation (with 915 rod) (1220, 1525mm rods can be selected according to the height of the tunnel). Fulfill 30m, Φ76mm long hole operation, optional rod magazine to unload the rod automatically.

♦Mobile remote control console and mobile working lighting.

♦With angle display.

♦Diesel engine self-drive, electric operation, with cable drum 80m.

♦Four-wheel drive, articulated chassis.

♦Comprehensive rock drilling speed 0.6m/min

♦Compact machine dimension: 7.2×1.6×2.58m

♦The propelling feed is provided with upper and lower tops to fix the angle of the advancing feed. A cleaning system is provided to clean up the magma of the propelling feed which is being produced while drilling upward.

Alloy propeller assembly

Heavy-duty propulsion feed pressed with wear-resistant aluminum alloy has high bending and torsional strength and long service life;

The surface is covered with stainless steel, and PTFE (solid lubricating block) wear-resistant liners are used between the moving parts, no need lubrication. Choose different drill pipe lengths (propulsion feed lengths) according to different tunnel sizes:

| Item | Head Parameters mm | ||

| Total length of propeller mm | 2732 | 3037 | 3412 |

| Length of the drilling rod | 915 | 1220 | 1525 |

Rod magazine can automatically connect and unload rods (optional).

Drilling rod magazine, capacity 21+1 rods, Select the appropriate drill rod specification according to the working conditions to realize the mechanized operation of automatic rod connecting and unloading. This option is not selected for particularly narrow tunnel.

♦ Hydraulic system

Adopting the direct-controlled rock drilling system of the American Sauer Danfoss hydraulic control system, the Danfoss plunger pump is the preferred pump for large-flow small and medium-sized trolleys, which is safe, efficient and stable. Equipped with automatic anti-jamming function, electromagnetic pump aerosol lubrication oil shortage shutdown protection and other functions. Equipped with a multi-faceted safety alarm system, the usability and safety are very high. If the fuel oil level is too low, the water temperature is too high, the hydraulic oil temperature is too high, etc., it has an alarm prompt.

♦ Rock Drill

Matching international brand high-power rock drills, according to the surrounding rock conditions and rock drilling needs, it can provide a variety of rock drilling options to obtain more economical and efficient rock drilling performance. Standard 18KW, optional 25KW.

♦ Drill boom support

It adopts a solid tray-type drill arm, which is stable, rotatable, pitched, and accurate in positioning. It is used for rock drilling in medium and deep holes, and is suitable for drilling vertical, inclined annular and fan-shaped blasting holes. Stable screw cylinder with high torque, high load capacity, no positional offset, ultra-compact, strong anti-pollution and durable.

♦ Carrier

The design of narrow fuselage and short boom is mainly considered to adapt to the operation of various specifications and cross-section sizes, especially for rock roadway or walking roadway walking in small roadways, and mining in 3-4 meters roadway, using narrow fuselage and small turning radius To facilitate flexible walking in small alleys. Two brake combinations

①Hydraulic closed brake; ②Reducer spring brake, the two-response delay is 0.5 seconds combined with the brake, the brake can be released, the trailer is simpler and more reliable, and it has the advantages of long towing distance and fast towing speed.

♦ Electrical system:

The electronic control components mainly use the international brand Schneider, which ensures the safety and reliability of the electronic control system.

The DL2 is a compact and flexible electro-hydraulic long hole drilling rig for long hole drilling operations in underground mine production, especially for long hole rock drilling in sub-pillarless sectional mining and other long hole drilling operations.

For drilling vertical, inclined annular and fan-shaped blasting holes, fully hydraulically driven rock drilling, capable of drilling 64-89 mm hole diameter, one-time rock drilling depth of 30 meters, sturdy, stable and specially designed long hole drilling arm to ensure propulsion Precise positioning and stable support of the feeds, guarantee high-quality drilling.

Diesel engine four-wheel drive tire chassis traveling, climbing ability 14 degree, The size of the working tunnel is: 3x3~4.5x4.3m (different drill pipe configuration), according to the requirements of the working conditions, the rod library function can be assembled to realize automatic rod connection and unloading and remote control.

Drilling vertical, inclined annular and sector blastholes with fully hydraulically driven rock drilling.

The mobile remote console helps the operator to grasp the drilling angle and hole depth more precisely.

The hydraulic control of the safety wet braking system on each wheel is adopted, the safety maintenance is simple, reliable, direct and low in failure, and the parking can realize automatic parking when the vehicle is stopped.

• Hydraulic control lift car shed

In line with FOPS (falling object impact) requirements, they hydraulic cylinder controls the liftting and lowering is suitable for the passage of short and small roadways.

• Pneumatic lube gun makes maintenance easier and simpler.

• Carry a high-pressure water gun on the vehicle for cleaning the vehicle, especially the cleaning of the propulsion part during operation, and reduce the wear of the accessories between the movement gaps.