- Tunnel Excavation Equipment

- Tunnel Drilling Jumbo

- Wheel Drilling Jumbo

- DW1-31 Wheel Drilling Jumbo

- DW2-50 Wheel Double Booms Drilling Jumbo

- DW1-24 Wheel Single Boom Drilling Jumbo

- DWE1-31N Wheel Single Boom Drilling Jumbo

- DW1-90 Single Boom Drilling Jumbo

- DW2-100 Wheel Drilling Jumbo

- Crawler Drilling Jumbo

- Level Surface Drilling Jumbo

- Big Slope Drilling Jumbo

- Dual Power Drilling Jumbo

- Rail Drilling Jumbo

- DR1-14 Rail Single Boom Drilling Jumbo

- Mining Drilling Jumbo

- Mining Production Drilling Rigs

- Mining Production Drilling Rigs

- Mucking Loader

- Crawler Mucking Loader

- Big Slope Crawler Mucking Loader

- Level Surface Crawler Mucking Loader

- Dual Power Crawler Mucking Loader

- Special Models Crawler Mucking Loader

- Open Pit Mucking Loader

- Narrow Size Mucking Loader

- Mucking Loader With Hammer (2 arms)

- Mucking Loader With Hammer(3 arms)

- Wheel Mucking Loader

- Track Mucking Loader

- LHD Loader

- Diesel LHD Loader

- LHD Loader Electrical

- Underground Truck

- Concrete Sprayer

- CPS25/CPS30 Concrete Sprayer

- ZTC30 Mobile Concrete Sprayer

- Mining Haulage Equipment

- Mining Wagon

- Shuttle Mining Car

- Side Dumping Wagon

- Forward Dumping Wagon

- Bottom Dumping Wagon

- Bottom Side Dumping Wagon

- Fixed Wagon

- Track Concrete Mixer

- Mobile Belt Conveyor

- Hangling Belt Conveyor

- Jack Hammer

- Hand-hold Rock Drills

- Air Picks

- Pneumatic Crusher

- Mining Locomotive

- Battery Locomotive

- Trolley Locomotive

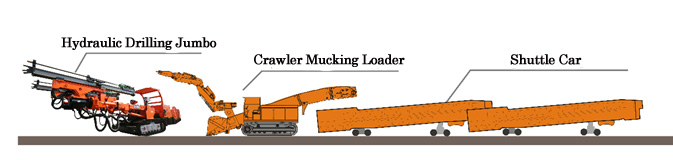

Introduction of DT2-30D Double Boom Jumbo:

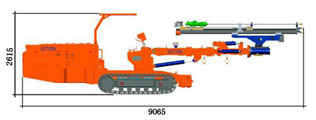

Combined with borehole and blasting, double boom mining jumbo drill can cooperate well with muck loaders. DT2-30 hydraulic underground crawler drilling jumbos are composed of drill booms, rock drills, hydraulic systems, and so on. Besides, optional configurations are offered to improve working performance. This jumbo offers a good working condition for operators.

1. Hydraulic Drill Boom

Double boom mining jumbo drill is equipped with special hydraulic drill boom.

(1) Blasthole distance is designed in high accuracy and parallelism so that location is precise and drilling speed is increased.

(2) Telescopic booms can make up drilling scale which is beyond drilling capacity of drill booms.

(3) In hydraulic underground crawler drilling jumbos, cross-section of main boom is in quadrate shape. In this way, drill boom accept stress more evenly. Besides, main boom can rotate within 180°.

2. Rock Drill

(1) DT2-30 double boom mining jumbo drill employs Montabert rock drill whose drilling efficiency is 2 to 4 times that of traditional ones.

(2) It can drill rocks whose maximum hardness is up to 15.

(3) Hydraulic compensation can decrease failures in drilling. Besides, to prolong working life of rock drill, the drill shank is specially designed to eliminate reactive force caused by impact force.

3. Hydraulic System

(1) To avoid cavitation erosion in oil pumps, we put oil tanks over oil pumps when designing hydraulic underground crawler drilling jumbos.

(2) DT2-30 double boom mining jumbo drill utilize multiple oil filter to guarantee high-purity oil, which can decrease working failure of hydraulic system.

(3) Oil flow volume in pumps is reasonable, which helps oil stay at suitable temperature.

(4) Hydraulic pressure is enlarged gradually to make a good transformation from boosting force to impact force.

(5) To make operation more comfortable, manual handle is applied.

4. Standard Configuration

Standard configurations of DT2-30 double boom mining jumbo drill are Montebert HC25 hydraulic rock drill, hydraulic cable drum, booster pump, air compressor, lift security ceiling (FOPS standard) and large-power working light.

5. Optional Configurations

Hydraulic pump and large/small-power diesel engine are optional for hydraulic underground crawler drilling jumbos.

| Drilling Speed | 0.8 - 2 m/min |

| Drill Boom Length | 3090/2475 mm |

| Drilling Hole Diameter | Φ28 mm - Φ102 mm |

| Hole Depth | 2700/2100 mm |

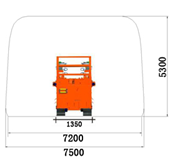

| Excavation Face (Width × Height) | ≤7.5 m × 5.3 m |

| Travel Speed | 25 m/min |

| Gradeability | ≤14° |

| Creeper Tread Width | 330 mm |

| Rock Drill | 2 × HYD200 |

| 2 × HC25/HC50 (Montebert optional) | |

| Dimension (Length × Width × Height) | 9065 × 1350 × 2615 mm |

| Weight | 12100 kg |

| Total Power | 77.2 kw |

| Main Electric Engine | 75 kw |

| Voltage | 380V - 1140V |

| Frequency | 50-60 Hz |

| Main Hydraulic pump | 2 × Plunger Pump + 2 × Plunger Pump |

| Max. Working Pressure | 20 Mpa |

| Oil Tank Capacity | 500 L |

| Cooling Medium | Water |

| Operation Panel | 2 |

| Boom Quality | 2 |

| Compensation | 1550 mm |

| Drilling Way | Hydraulically Translational Motion |

| Rotation | ± 180° |

| Boom Swing Scale | 14°/ 35° |

| Lifting Scale | +55°/ -16° |

| Pitching Up/Down (Impeller) | +35°/-15° |

| Swing Scale (Impeller) | +35°/-12° |

| Telescopic Length | 850 mm |