- Tunnel Excavation Equipment

- Tunnel Drilling Jumbo

- Wheel Drilling Jumbo

- DW1-31 Wheel Drilling Jumbo

- DW2-50 Wheel Double Booms Drilling Jumbo

- DW1-24 Wheel Single Boom Drilling Jumbo

- DWE1-31N Wheel Single Boom Drilling Jumbo

- DW1-90 Single Boom Drilling Jumbo

- DW2-100 Wheel Drilling Jumbo

- Crawler Drilling Jumbo

- Level Surface Drilling Jumbo

- Big Slope Drilling Jumbo

- Dual Power Drilling Jumbo

- Rail Drilling Jumbo

- DR1-14 Rail Single Boom Drilling Jumbo

- Mining Drilling Jumbo

- Mining Production Drilling Rigs

- Mining Production Drilling Rigs

- Mucking Loader

- Crawler Mucking Loader

- Big Slope Crawler Mucking Loader

- Level Surface Crawler Mucking Loader

- Dual Power Crawler Mucking Loader

- Special Models Crawler Mucking Loader

- Open Pit Mucking Loader

- Narrow Size Mucking Loader

- Mucking Loader With Hammer (2 arms)

- Mucking Loader With Hammer(3 arms)

- Wheel Mucking Loader

- Track Mucking Loader

- LHD Loader

- Diesel LHD Loader

- LHD Loader Electrical

- Underground Truck

- Concrete Sprayer

- CPS25/CPS30 Concrete Sprayer

- ZTC30 Mobile Concrete Sprayer

- Mining Haulage Equipment

- Mining Wagon

- Shuttle Mining Car

- Side Dumping Wagon

- Forward Dumping Wagon

- Bottom Dumping Wagon

- Bottom Side Dumping Wagon

- Fixed Wagon

- Track Concrete Mixer

- Mobile Belt Conveyor

- Hangling Belt Conveyor

- Jack Hammer

- Hand-hold Rock Drills

- Air Picks

- Pneumatic Crusher

- Mining Locomotive

- Battery Locomotive

- Trolley Locomotive

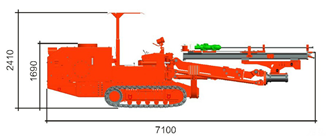

Description of DT1-14 Single Boom Jumbo:

Single boom jumbo, also called single boom underground drilling jumbo, is mainly applied in tunneling construction of mining, metallurgy, water and electricity, railway, highway engineering, etc. It can work on surface of the tunnel, roof, side and floor. The single boom jumbo can not only drill the blast hole, but also drill the bolt hole easily.

1. Hydraulic Drill Boom of Single Boom Jumbo

1) High Efficiency: Unique translation design of drill boom improves accuracy and parallelism of borehole spacing, which achieves accurate and quick positioning.

2) 360º Punching Range: Telescopic boom compensates displacement difference generated by drill arm when moving downward.

3) Stable Force: The square cross-section beam design of upper arm makes overall force on drill boom more stable.

4) Flexible Movement: Rotary motor in the front of upper arm makes the whole feed mechanism move flexibly (± 180°).

2. Rock Drill of Single Boom Jumbo

1) High Efficiency: Rock drill we employed is imported from France Montebert. It can be used to drill rock with high hardness, whose efficiency is two to four times of traditional handheld rock drill. Imported rock drill has hydraulic compensation system, which can prevent failed hit caused by operation errors.

2) Long Service Life: Special shank structure is designed to eliminate reaction of the strike, which can extend service life of rock drill.

3. Hydraulic System of Single Boom Jumbo

1) Oil Tank above Pump Motor: Oil tank is placed on the top and pump motor is erected over the bottom, which solves the defects of traditional jumbo "tank located in low position and pump located in high position". This design avoids oil pump cavitation caused by failed suction of oil pump.

2) Multiple filtration system improves oil cleanliness and reduces failure of hydraulic system.

3) Rational pump flow and efficient water cooler ensure that the system can maintain normal oil temperature after long hours' working.

4) Single boom drilling jumbo adopts stepwise compression technology, which optimizes the match between propelling force and impact force, and improves the positioning and drilling efficiency.

5) It is also equipped with a manual four direction control lever.

4. Standard Configuration of Single Boom Jumbo

1) Large Power Work Light.

2) Hydraulic Air Compressor.

3) Liftable and Lowerable Safety Ceiling (Conforming with FOPS Requirement).

5. Optional Configuration

1) Hydraulic Water Pump.

2) Large/Small Power Diesel Engine.

| Drill Speed | 0.8 to 2 (m/min) |

| Drill Rod Length | 3090 mm |

| Drill Diameter | Φ 28 mm to 102 (mm) |

| Hole Depth (Once) | 2700 mm |

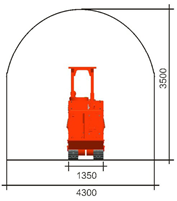

| Cross Section (W × H) | ≤ 4.3 × 3.5 (m) |

| Traveling Speed | 10 m/min |

| Climbing Capability | ≤18° |

| Track Plate Width | 270 mm |

| Rock Drill Number and Type | One HYD200 (Lotus Hill) |

| One HC25/HC50 (Montebert Optional) | |

| Overall Dimensions (L × W × H) | 7100 × 950 × 1690 (mm) 2410 mm (Ceiling Height) |

| Total Weight | 7600 kg |

| Total Power | 39.2 kw |

| Motor Power | 37 kw |

| Voltage | 380 to 1140 (V) |

| Frequency | 50 to 60 (Hz) |

| Main Hydraulic Pump (Standard Configuration/High Configuration) | Three Gear Pumps (Standard Configuration) |

| One Plunger Pump and One Gear Pump (High Configuration) | |

| Maximum Working Pressure (MWP) | 20 Mpa |

| Oil Tank Capacity | 240 L |

| Heat-Dissipating Method | Water |

| Operation Panel | One Set |

| Arm Number | One Set |

| Compensation Journey | 1500 mm |

| Boom Moving Type | Mechanical Translation |

| Rotation Angle (Positive/Negative) | ± 180° |

| Swing Angle (Inside/Outside) | ± 32° |

| Rise/Fall Angle | + 45/- 15 (°) |

| Pivot Angle Up/Down | 35 + 16/10 (°) |